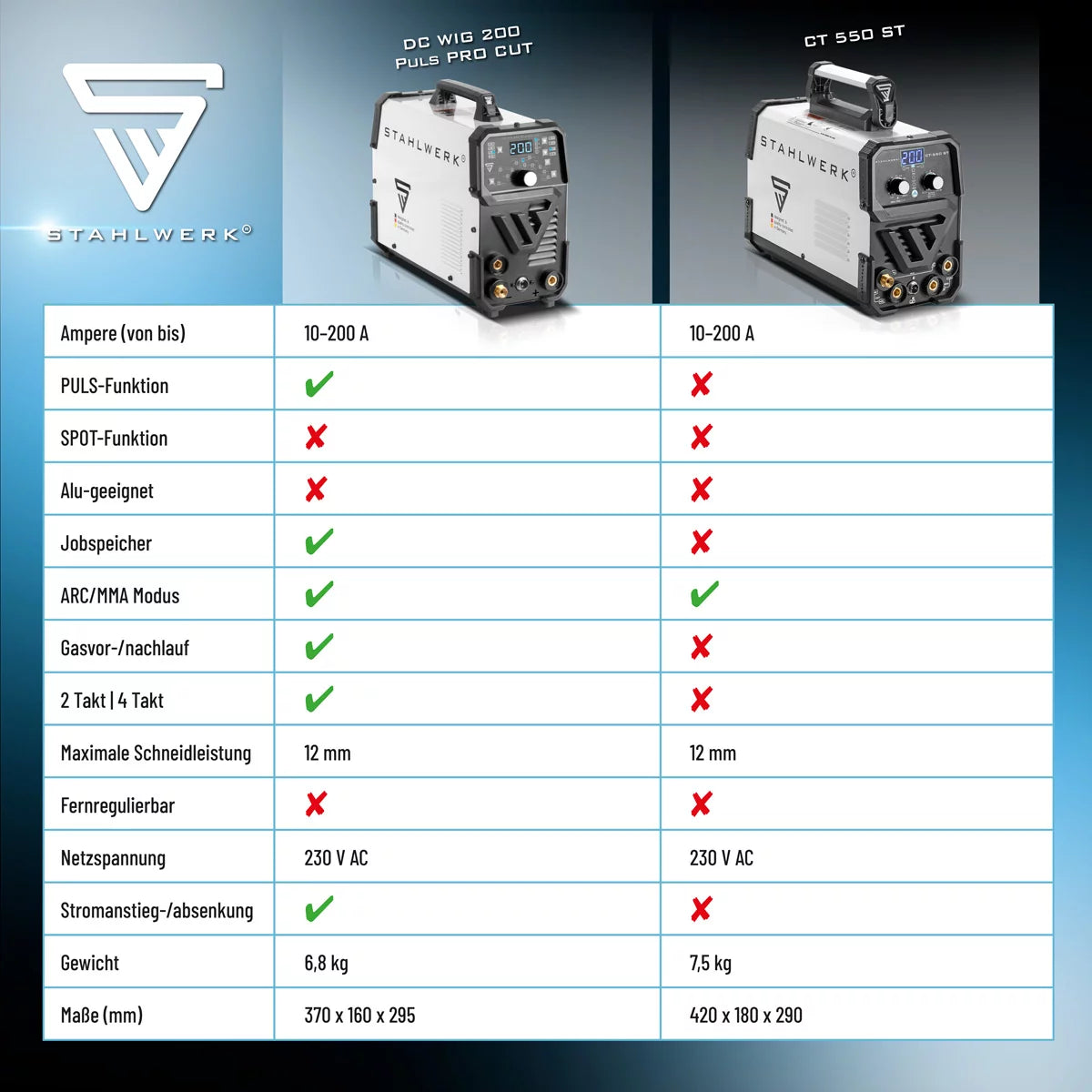

Steelworks 3 in 1 combi welding device CT 550 ST IGBT with electrode and plasma function / DC WIG MMA welding device with plasma cutter up to 12mm, 200 ampere WIG / MMA + 50 A cut

Technical data

Technical data

| Output current (WIG / MMA / CUT) | 10-200 A (WIG / MMA) / 20-50 A (cut) |

| Type of protection | IP21S |

| Mains voltage | 1 x 230 V AC (+-15%) |

| Network frequency | 50/60 Hz |

| Maximum network current (i1max) (WIG / MMA / CUT) | 31.5 / 42.3 / 37.5 a |

| Largest effective network current (i1eff) (WIG / MMA / CUT) | 12.2 / 13.4 / 11.9 a |

| Air pressure | Min. 4 bar |

| Air flow | Min. 100 l / min |

| Weight | 7.5 kg |

| Dimensions L x W x H (mm) | 420 x 180 x 290 |

| Network connection | CEE 7/7 Schuko plug with CH sockets fixed adapter |

| Stand up | IEC 60974-1; EN 60974-10 (Class A) |

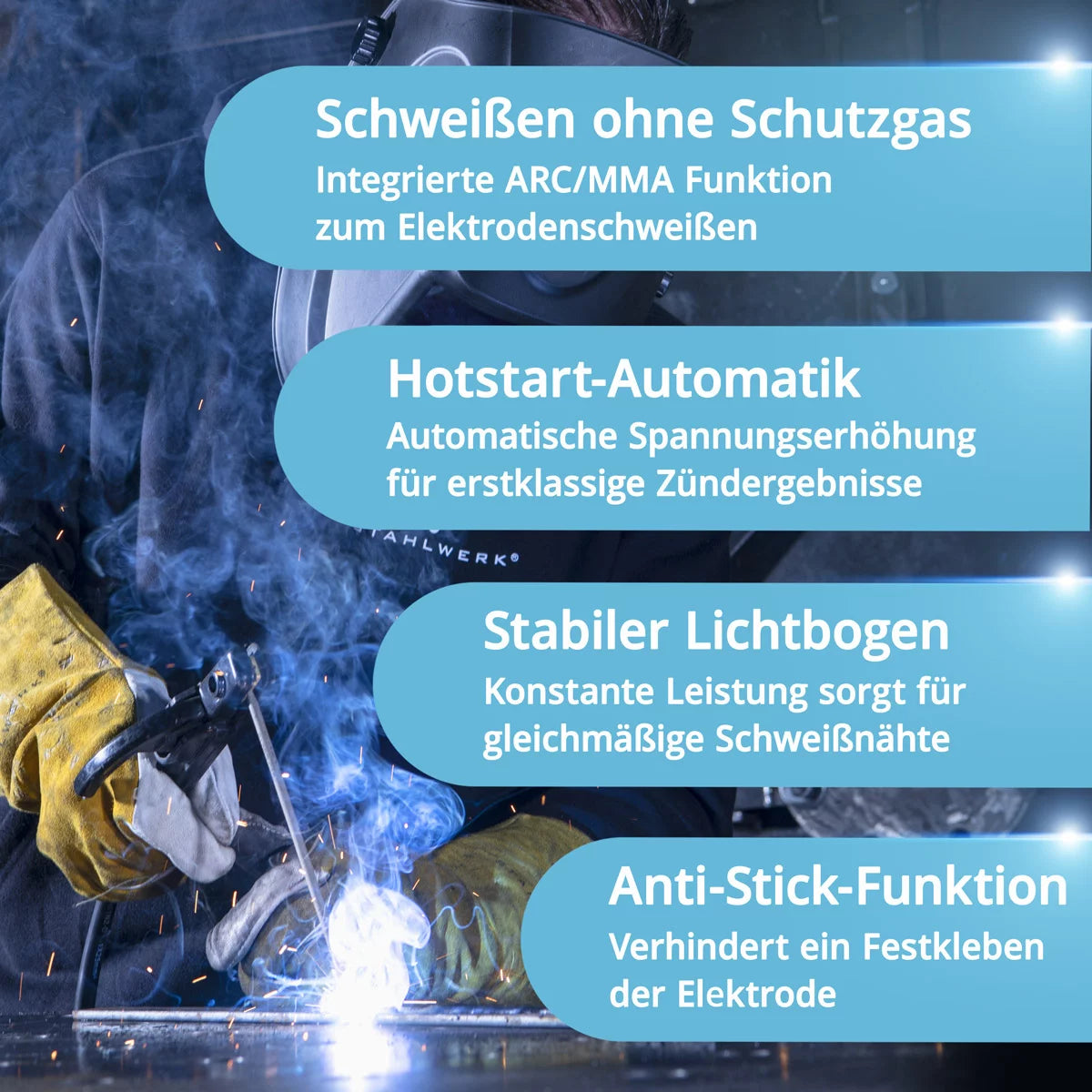

Functions

Properties & advantages

Scope of delivery