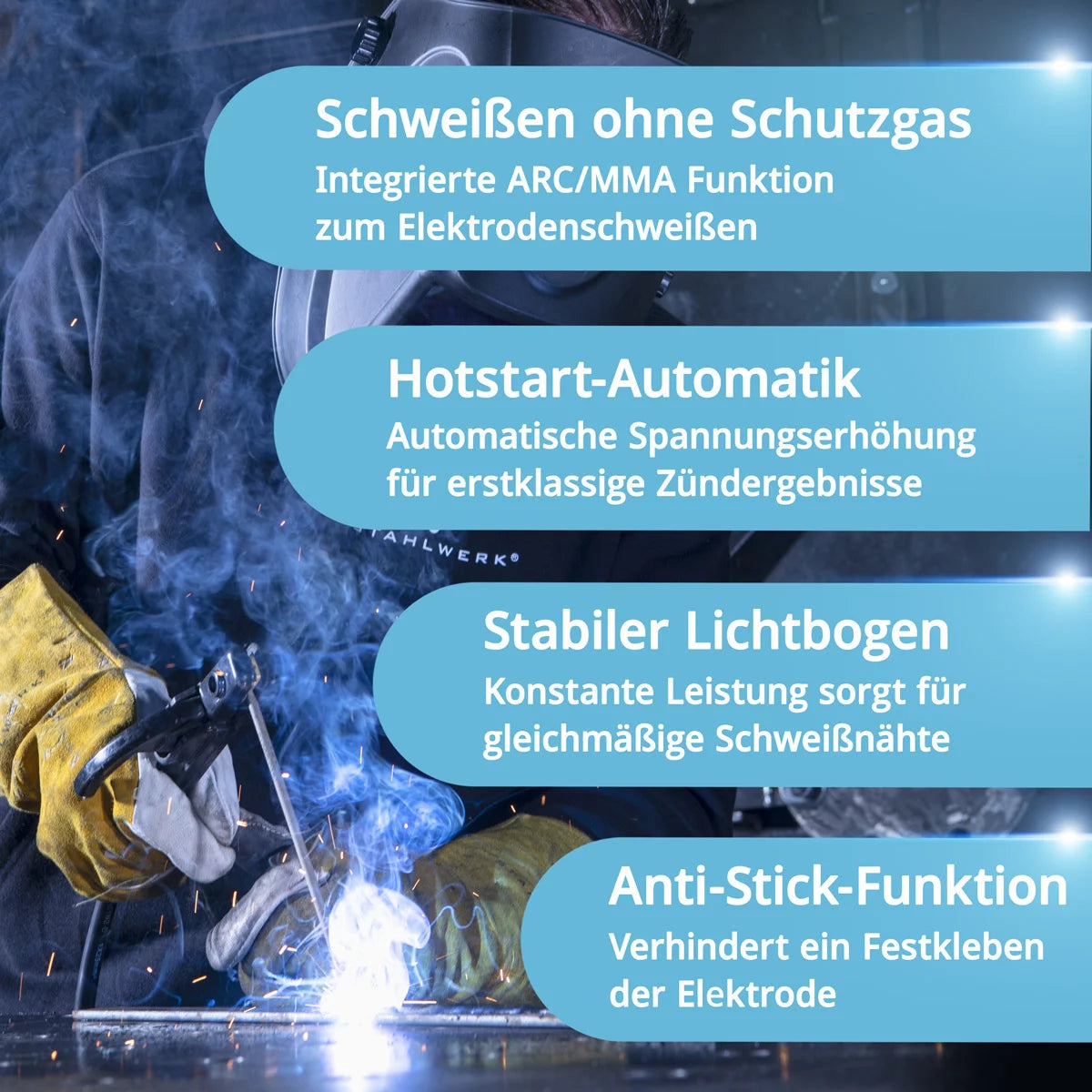

Properties & advantages

- The welding machine supplies the highest efficiency & performance - single -phase change current (230 V) and allows a output of real 160 amps.

- Smart cooling & overheating protection - the latest technology, integrated overheating protection and high performance cooling enable the maximum performance.

- Fill wire-All of our devices can use fill wire (flux-cored wire). This enables welding without protective gas.

- Automatic wire feed - the speed of the wire feed is automatically regulated via the set welding current.

- Automatic voltage control (volt) - The voltage automatically adapts to the set welding current.

- Trolling roller - standard wire roles 1 kg can be processed here. The roundworm can accommodate 16 mm coils.

- Wire drive roller - by the simple change of the

Drive roller can be used by different wire thicknesses (0.6 mm /

0.8 mm / 1.0 mm). - MMA electrode welding / MMA welding - is a universal welding process. No protective gas is required.

- Lift Tig - With the enclosed WP -17V hose package, the device can also be welded (string ignition).

Notice: Note the correct current for a perfect welding result:

At least 60 amps are required for welding 0.6 wire

At least 80 amps are required for welding 0.8 wire

At least 100 amps are required for welding at 1.0 wire

Notice: The device is not for use in

Residential areas in which the power supply via a

public low -voltage supply system. It can, both

through line -bound and radiated disturbance, possibly

be difficult, electromagnetic tolerance in these areas

to ensure.