Properties & advantages

- Job storage - The industrial welding device has memory options for self -configured settings / presets. The system can save 100 parameters for the welding process and call up, which significantly improves the reproducibility and usability of the welding process.

- Preflow / gas lead - thanks to the gas flow, the protective gas flow begins before the arc is ignited. This prevents the workpiece from getting in touch with air at the start of welding. This protects the weld seam from oxidation. Depending on the sweat requirement, the gas lead time can be set individually.

- MIG MAG - metal protection gas welding with DC (DC). It can be welded with inactive / inerts (MIG, e.g. Argon) or with active (MAG, e.g. CO²) gases. Gas and welding wire come from a burner head and enable welding work to be carried out with just one hand.

- Inductance - The individual setting of inductance makes it possible to avoid the increased formation of welding injections.

- Stabilization system - The digital control of the welding process continuously ensures high -quality work results. Thanks to automatic stabilization, the welding system reacts directly to changes in the supply voltage and is therefore also suitable for networks in which voltage waste can occur.

- Fully syngical device - The voltage (volt) and the wire feed is automatically suitable for the set welding current. The inverter is therefore particularly easy to use.

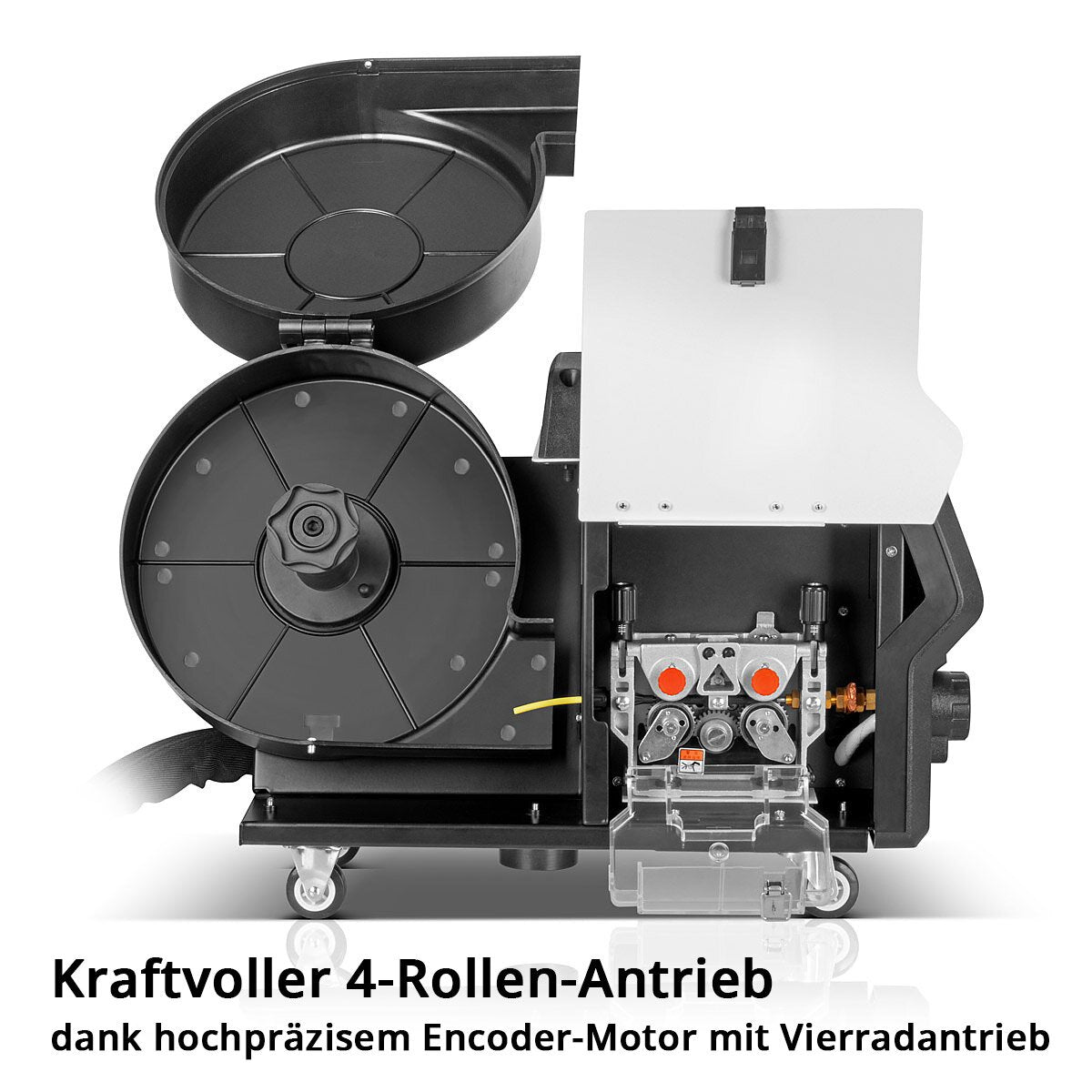

- The use of a wire feed device with a high-precision encoder engine with a four-wheel drive and a full digital wire feed control system ensure a smooth and stable feed.

- 4 Role drive - reliable and powerful wire feed. Thanks to 4 drive rollers, thicker wires are continuously and safely encouraged.

- Automatic voltage control (volt) - The voltage automatically adapts to the set welding current.

- Trolling roller - commercially available 5 kg and 15 kg wire rollers can be processed. The universal pulendorn can absorb 50 mm coils. Optionally, 200 mm coils can also be processed with an adapter.

- Wire drive rollers - Due to the easy change of drive rollers, various wire thicknesses of 0.8 to 1.6 mm can be used. By switching to drive rollers with 'U' profile, aluminum wire can also be used.

- Smart cooling & overheating protection-the latest technology, integrated overheating protection and high-performance cooling enable the maximum performance to be called up.

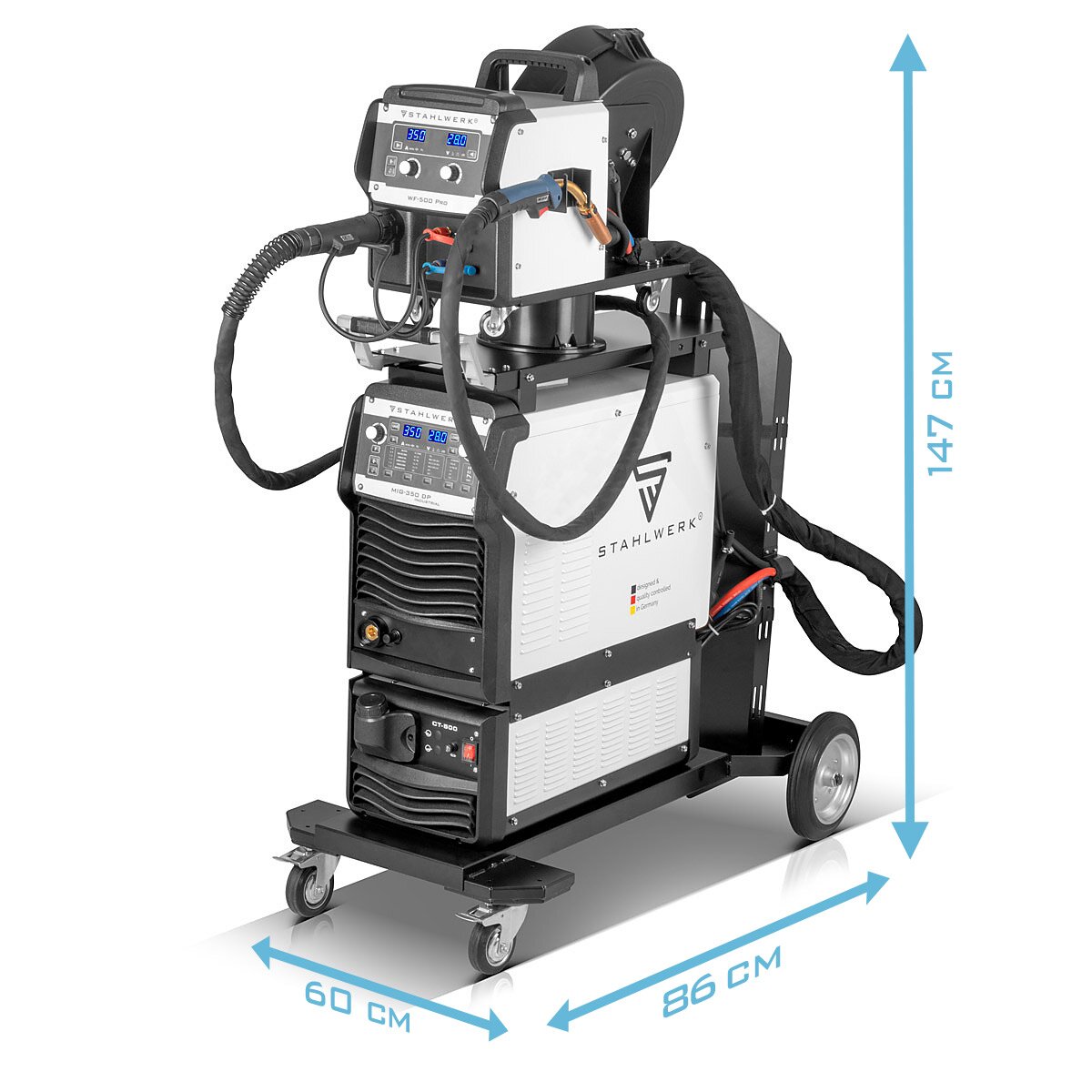

- Due to the compact dimensions and the low weight, the flexible welding machine is particularly suitable for mobile use in industry, on construction sites and assembly.

A notice: The device is not intended for use in living areas in which the power supply is carried out via a public low -voltage supply system. It may be difficult to ensure electromagnetic tolerance in these areas, both through line -bound and emitted disturbance.

A notice: Please note that the carbon soul was designed exclusively for processing aluminum and stainless steel. Please always use a steel soul to weld steel to avoid damage!