Steelworks industrial welding machine MAG 500 DP full-syngian, water-cooled IGBT Inverter with 500 A and spot function, MIG MAG WEISS system with pulse | Double pulse | High-speed pulse

Designed for the highest demands in industrial use: The water -cooled steel mill MIG MAG 500 DP welding machine promises maximum performance even under the toughest conditions with 500 ampers. Equipped with the latest IGBT technology of the latest generation, the high-quality welding machine convinces with the highest level of performance and efficiency. The 1.6 kW water cooling enables efficient water circulation and reliable heat removal of hose package and welding burner. This ensures stable temperature conditions and longer work cycles when welding. Robust built, vibration and dust and splash-protected, the reliable welding machine masters every welding. The high efficiency of the inverter ensures high welding speeds and first -class welding results. The professional welding device can be easily operated via a clear panel and the desired welding parameters are quickly set. In addition to steel and stainless steel, the versatile industrial welding machine is particularly suitable for aluminum, copper and nickel-based alloys. In addition, the welding system either has a fully syngian and manual mode in order to optimally adapt to the needs and requirements of the welder. The individual setting of inductance makes it possible to avoid the increased formation of welding injections. The digital control of the welding process continuously ensures high -quality work results. Thanks to automatic stabilization, the welding machine reacts directly to changes in the supply voltage and is therefore also suitable for networks in which voltage waste can occur. The industrial device is equipped with both an analog and a digital interface, so that the welding robots fanuc | Fig | Kuka | Yaskawa and other welding robot systems are compatible. Due to the compact dimensions and the low weight, the flexible welding machine is particularly suitable for mobile use in industry, on construction sites and assembly.

Technical data

Technical data

| Model | Steelworks welding machine MIG MAG 500 DP |

| Starting current MIG | 60-500 a |

| Switching time MIG (40 ° C) | 100% at 500 a |

| Mains voltage | 400 V (+-15%) 3 ~ |

| Type of protection | IP23S |

| Network current frequency | 50/60 Hz |

| Maximum network current (I1max) MIG | 38 a |

| Largest effective network current (i1eff) MIG | 38 a |

| Welding current | 60-500 a |

| Switching time at 40 ° C | 100 % |

| Cooling system | Air/fluid cooling |

| Cooling capacity | 1.6 kW |

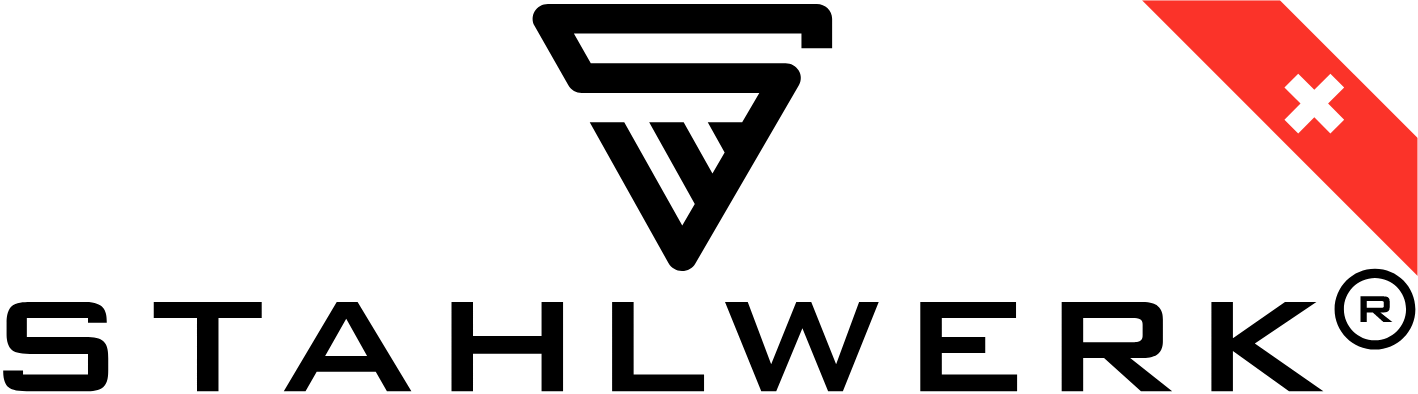

| Total dimensions | 1,470 x 600 x 860 mm |

| Net weight | 110 kg |

| Network connection | CEE plug, 63a, 5-pin |

| Stand up | EN 60974-1: 2018+A1: 2019, EN 60974-10: 2014+A1: 2015 (Class A) |

Functions

- Designed for the highest demands in industrial use: The water -cooled steel mill MIG MAG 500 DP welding machine promises maximum performance even under the toughest conditions with 500 ampers.

- Numerous welding parameters- the versatile industrial welding machine is particularly suitable for steel and stainless steel, especially for aluminum, copper and nickel-based alloys and for thin sheet.

- Kombigerät-powerful MIG likes welding machine with 500 amps and spot function including pulse / double pulse / high-speed pulse.

- The industrial device is equipped with an analog and a digital interface, so that it is compatible with the welding robots Fanuc / ABB / Kuka / Yaskawa and other welding robot systems.

- Spot dot welding function-particularly suitable in the car area for thin body parts. As a result, the issue points are precisely reproducible and even.

- MIG PULS - The pulse function keeps the heat input low and the welding of aluminum enables.

- Double pulse - The double pulse function gives high -quality weld seams with an exact scaling.

- High-speed pulse-The function of high-speed impulse welding and welding with a large melting depth promises a 30% higher efficiency. Precise arc recognition ensures the stability of the impulse light sheet.

- The 1.6 kW water cooling enables efficient water circulation and reliable heat removal of hose package and welding burner. This ensures stable temperature conditions and longer work cycles when welding.

- IGBT Technology - equipped with the latest IGBT technology of the latest generation, impresses the high -quality welding machine with the highest level of performance and efficiency as well as a high switching duration (ED).

- Job storage - The industrial welding device has memory options for self -configured settings / presets. The system can save 100 parameters for the welding process and call up, which significantly improves the reproducibility and usability of the welding process.

Properties & advantages

- Preflow / gas lead - thanks to the gas flow, the protective gas flow begins before the arc is ignited. This prevents the workpiece from getting in touch with air at the start of welding. This protects the weld seam from oxidation. Depending on the sweat requirement, the gas lead time can be set individually.

- MIG MAG - metal protection gas welding with DC (DC). It can be welded with inactive / inerts (MIG, e.g. Argon) or with active (MAG, e.g. CO²) gases. Gas and welding wire come from a burner head and enable welding work to be carried out with just one hand.

- Inductance - The individual setting of inductance makes it possible to avoid the increased formation of welding injections.

- Stabilization system - The digital control of the welding process continuously ensures high -quality work results. Thanks to automatic stabilization, the welding system reacts directly to changes in the supply voltage and is therefore also suitable for networks in which voltage waste can occur.

- Fully syngical device - The voltage (volt) and the wire feed is automatically suitable for the set welding current. The inverter is therefore particularly easy to use.

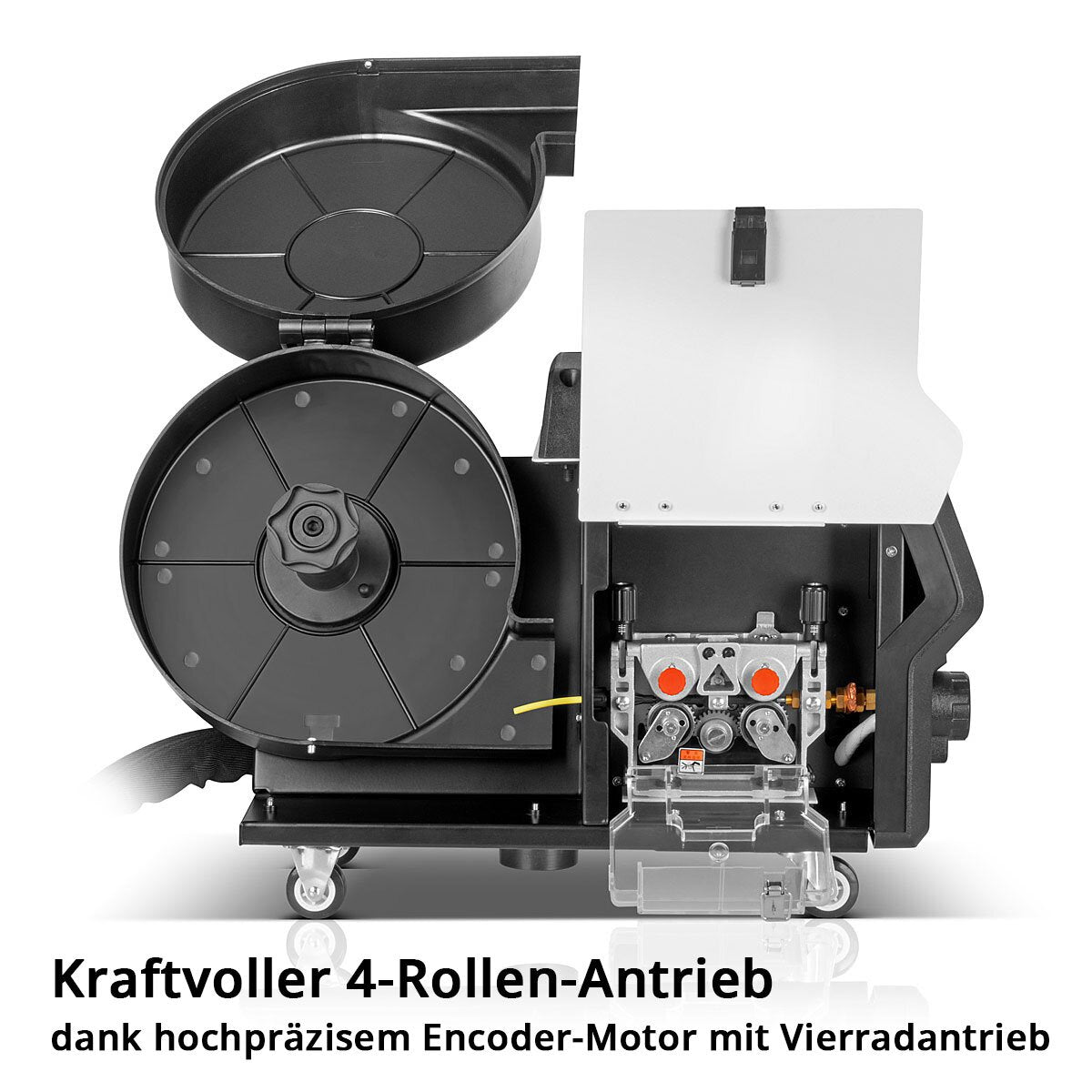

- The use of a wire feed device with a high-precision encoder engine with a four-wheel drive and a full digital wire feed control system ensure a smooth and stable feed.

- 4 Role drive - reliable and powerful wire feed. Thanks to 4 drive rollers, thicker wires are continuously and safely encouraged.

- Automatic voltage control (volt) - The voltage automatically adapts to the set welding current.

- Trolling roller - commercially available 5 kg and 15 kg wire rollers can be processed. The universal pulendorn can absorb 50 mm coils. Optionally, 200 mm coils can also be processed with an adapter.

- Wire drive rollers - Due to the easy change of drive rollers, various wire thicknesses of 0.8 to 1.6 mm can be used. By switching to drive rollers with 'U' profile, aluminum wire can also be used.

- Smart cooling & overheating protection-the latest technology, integrated overheating protection and high-performance cooling enable the maximum performance to be called up.

- Due to the compact dimensions and the low weight, the flexible welding machine is particularly suitable for mobile use in industry, on construction sites and assembly.

A notice: The device is not for

use in living areas in which the power supply

via a public low -voltage supply system. It can

Both through a cable and radiated disorder

may be difficult in these areas of electromagnetic

To ensure compatibility.

A notice: Please note that

The carbon soul exclusively for processing aluminum and

Stainless steel was designed. For welding steel please always one

Use steel soul to avoid damage!

Scope of delivery

- 1 x steel mill welding machine Mig Mag 500 DP

- 1 x wire feed unit WF-500 Pro

- 1 x cable strand in fabric coat: 2 x cooling water hoses with

Pre -assembled quick couplings, 1 x gas hose with hose clamps, 1

x power connection cable 70 mm² with 13 mm thorn plug, 1 x 10-pin

Control cable - 1 x device car with 2 steering and 2 rigid rollers,

Holding device for gas bottles, 1 x grid for gas bottles

pre -assembled - 2 x wire guide rolls 1.0/1.2 and 1.2/1.6 U-profile, 0.8/1.0 V profile (1.2/1.6 already installed in the device)

- 2 x additional tooth wheel wire roller wearers

- 1 x rear wire guide socket (with steel intake, Teflon recording pre -assembled)

- 1 x medium wire guide socket

- 1 x hose package MB501D (Binzel) 3 m water -cooled

- 1 x carbon soul 3 m (Binzel)

- 1 x hose package holder

- Electricity nozzles 1 x 0.8, 2 x 1.0, 2 x 1.2 (1 x 1.2 pre -assembled), 2 x 1.6

- 1 x mass screw clamp 3 m, 70 mm² with 13 mm thorn plug

Our recommendations

7 year guarantee*

On everything - except wear parts

Money-back guarantee

Uncomplicated return and reimbursement of the purchase price 30 days after purchase

Hotline: +41 76 604 54 05

Mon. to Fri. from 10:00 a.m. to 12:00 p.m. and from 1:00 p.m. to 5:00 p.m. Telephone advice & technical support by qualified specialist staff

Email support

Tell us your request via contact form or directly to info@stahlwerk-schweiz.ch