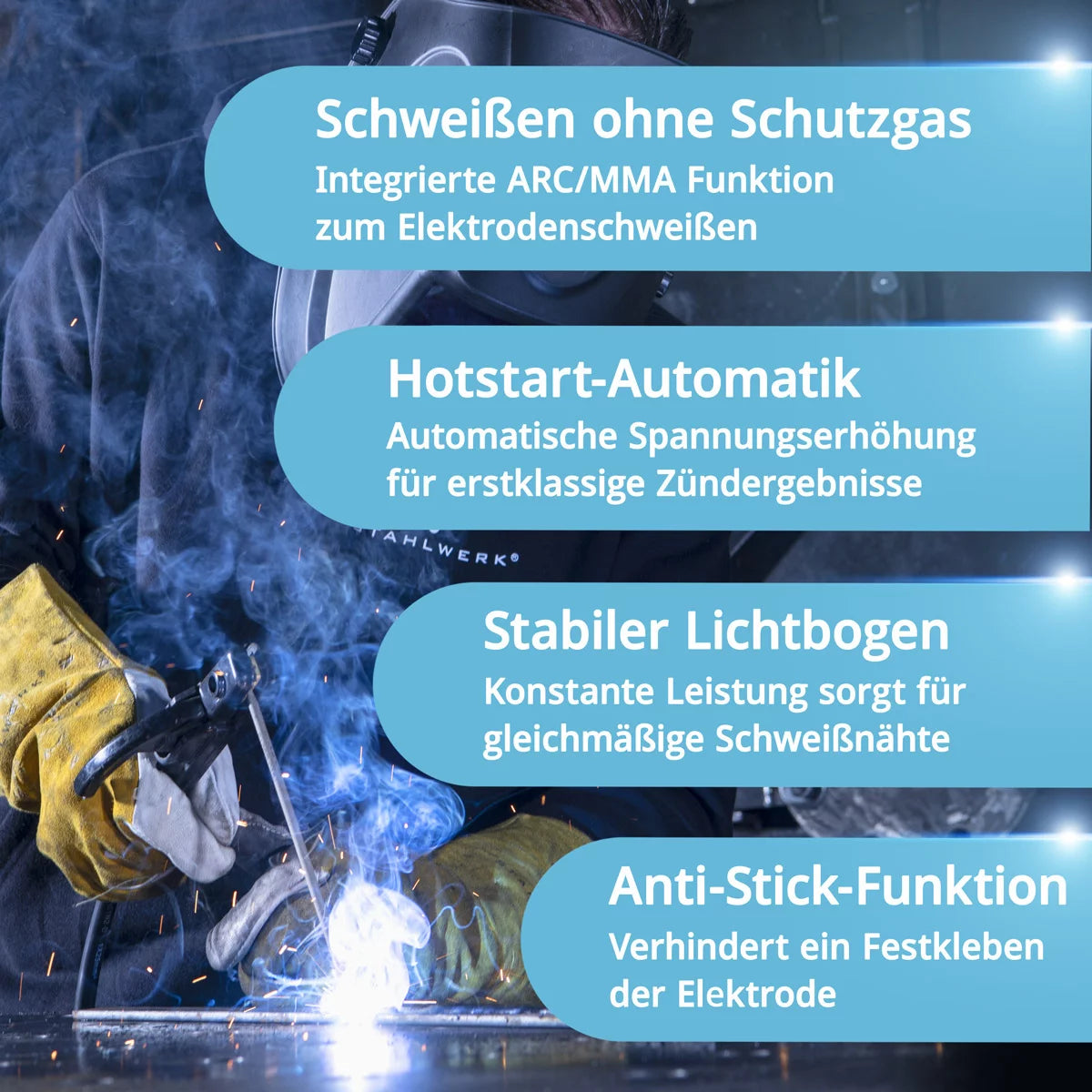

STAHLWERK welding machine FLUX 140 ST Digital Lift TIG starter set with 140 A, synergic wire feed, Lift-TIG and ARC/MMA function for welding without protective gas

Technical data

Technical data

| Model: | STAHLWERK FLUX 140 ST digital welding machine |

| Output current FLUX | TIG | MMA: | 20 - 140 A | 20 - 120 A (TIG/MMA) |

| Duty cycle FLUX (40°C): | 15% at 140 A / 60% at 70 A / 100% at 54 A (FLUX) |

| Duty cycle TIG | MMA (40°C): | 15% at 120 A / 60% at 60 A / 100% at 46 A (TIG/MMA) |

| Open circuit voltage U0: | 62V |

| Maximum mains current (I1max): | 21 A | 20.6A | 14.5A (FLUX/MMA/TIG) |

| Largest effective mains current (I1eff): | 8.1A | 8A | 5.6A (FLUX/MMA/TIG) |

| Protection class: | IP21S |

| Mains voltage: | 1 x 230V AC |

| Mains frequency: | 50/60Hz |

| Weight: | 7kg |

| Dimensions L x W x H (mm): | 395x205x345 |

| Mains connection: | CEE 7/7 Schuko plug |

| Standards: | IEC 60974-1; EN 60974-10 (Class A) |

| Certified by: | SGS Standards Technical Services Co., Ltd. |

Functions

Properties & advantages

Scope of delivery